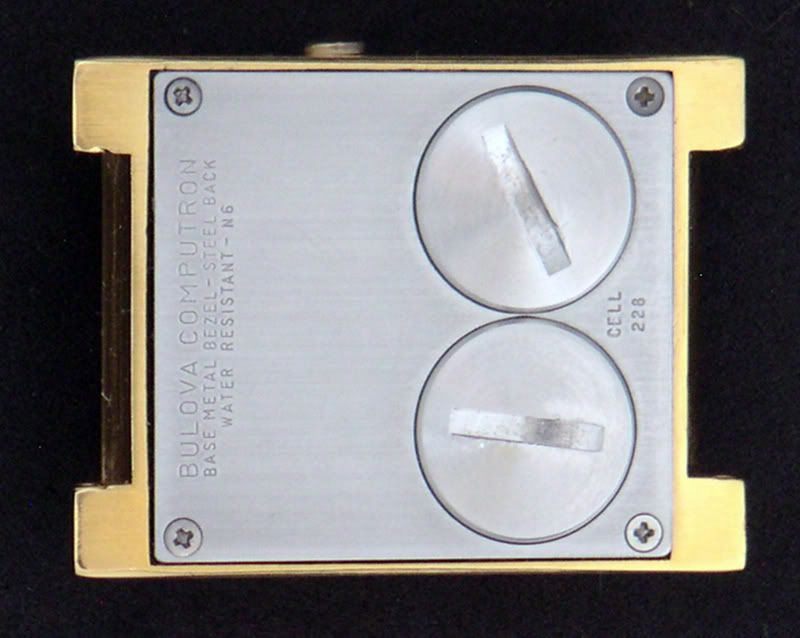

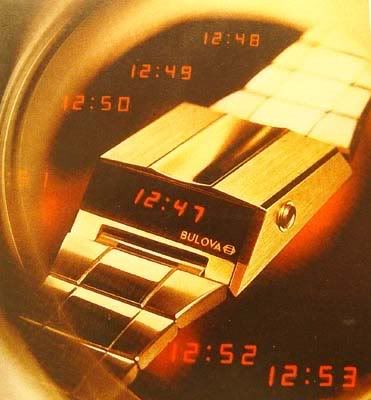

Okay, I will try to answer some questions. The following watch has a 20micron plated case:

as stamped between the lugs. After 42 years absolutely no wear through. The Bulova driver was plated to 10 microns, similar to the original Bulova plating.

I thought about removing the plugs but did not want to risk damaging them. Also did not know which way they are inserted, whether or not they are tapered to fit etc. They are not filed to flush but were well worn to the case so appear to be flush now.

The pushers did not need plating strangely enough but I have also plated these with the copper wire method.

The watch has been pressure tested in my friends Bulova vacumn tester and passed with no leaks. The Bulova tester comes up on Ebay occasionally and comprises of the following:

A hand pumped vacumn chamber and liquid soap. Like testing an inner tube, apply the liquid soap around the buttons and the case back to case seam. Place in chamber and create the vacumn. Any leaking air will cause bubbles to form. No bubbles, then at the least, water resistant to rain, probably better then that but I am conservative when it comes to water. The tester says good to 30m.

Hope this helps. I have had quite a few of the vintage winding watches plated here and have absolutely no wear problems, even when dressing the case for graining so I know it is a durable finish.

Most of my Omegas have gold caps on stainless. This is a real gold, one piece, 120 micron cap that is bonded to the steel case with heat and pressure. It is almost like Rolled Gold Plate in that dense real gold is used to cover the base metal. The problem with plating is that it is very porous to chemical intrusion although it looks and polishes correctly. If there is a large pore or flaw in the plating then the acids of the skin can penetrate through the plating and corrode the base metal (usually brass).

Hope this helps, the watch by the way looks much better in person then on the photos, not as harsh.

Cheers, Geoff